Tempering vs. Annealing

Metal workpieces are often heat treated to improve their physical, mechanical, and/or chemical properties to better suit their manufacturing operations and/or intended applications. Some of the characteristics that can be affected include strength, hardness, formability, ductility, malleability, and machinability.

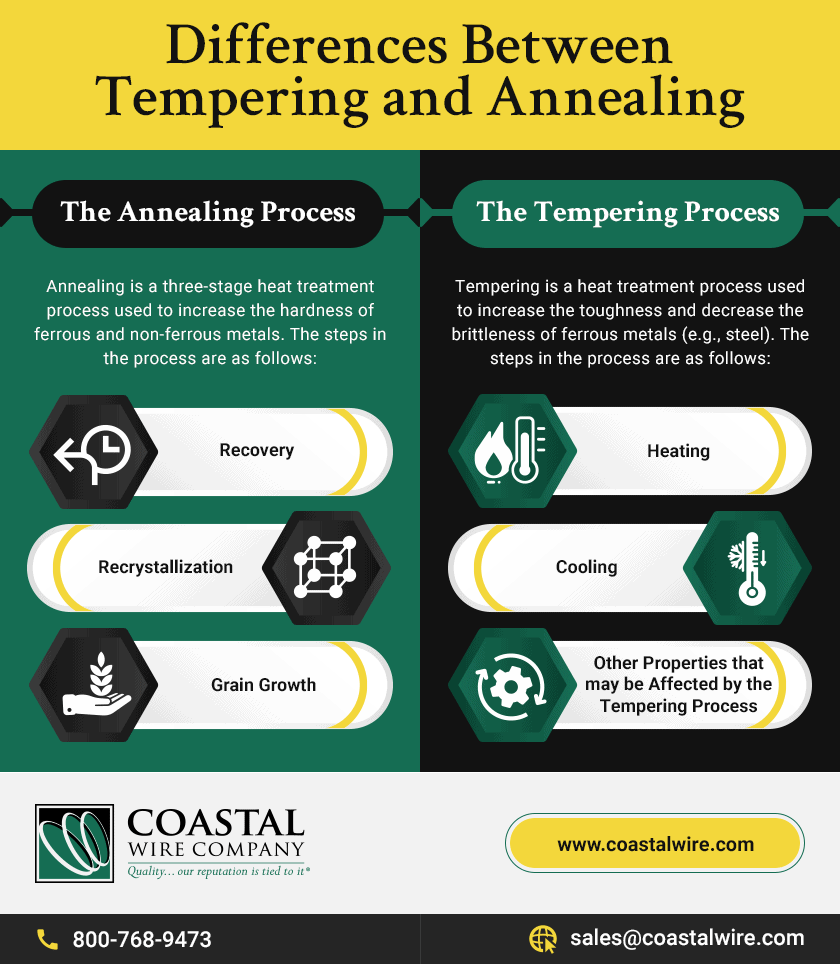

Two of the most commonly utilized heat treating methods are tempering and annealing. Below, we highlight the differences between them as well as typical use cases for annealed workpieces.

Differences Between Tempering and Annealing

The Annealing Process

Annealing is a three-stage heat treatment process used to increase the hardness of ferrous and non-ferrous metals. The steps in the process are as follows:

- Recovery. The metal workpiece is heated—typically by a furnace—to a temperature where the material’s internal structures start to relax.

- Recrystallization. The heated workpiece is heated even further to above the material’s recrystallization temperature but below its melting temperature. Holding the workpiece at this point allows new grains to develop within the material’s internal structure without forming preexisting stresses.

- Grain Growth. The grains that began developing during the previous stage are allowed to fully develop. Carefully controlling the cooling process (i.e., the rate of cooling) ensures the growth of grains results in a less hard, more ductile material.

The Tempering Process

Tempering is a heat treatment process used to increase the toughness and decrease the brittleness of ferrous metals (e.g., steel). The steps in the process are as follows:

- Heating. The metal workpiece is heated to a precise temperature below its critical point. Once the temperature is reached, it is held for a set amount of time. Both the temperature and the holding time depend on the material.

- Cooling. After the workpiece has been held at the proper temperature for the right amount of time, it is quickly cooled in a process known as quenching. Various quenching methods can be used, including immersing the workpiece in water, oil, or compressed air.

Other properties that may be affected by this heat treatment include:

- Ductility

- Hardness

- Strength

- Structural Stability

Products That Benefit From Annealing

Annealing can enhance many properties in a metal. For example, it can increase the material’s strength, hardness, elasticity, formability, or ductility, all of which make it easier to manufacture the desired parts and products and/or improve the components’ performance in the intended applications. That’s why many manufacturers choose to use annealed materials in their production operations.

In the wire making industry, some of the products that are commonly made out of annealed metals are:

- Black annealed wires. These wires are named after their distinctive black color, which is the result of an anti-corrosive surface coating added after the annealing process. They are used in both industrial and consumer applications, such as baling and handcrafting.

- Bright wires. These wires are named after their bright and smooth finish. They are generally used in binding and tying applications.

- Merchant wires. These wires consist of multiple larger coils of annealed wire that are wound onto a stand.

- Box wires. These wires refer to small and tight coils of annealed wire that are individually packed into boxes.

- Tie wires. These boxes are designed for use in tying applications. They generally come packaged as merchant wire or box wire.

Learn More About Heat Treatments From Coastal Wire Co.

Want to learn more about annealing and how it compares to other heat treatments? Ask the experts at Coastal Wire Co. We are a premier provider of high-quality wire specializing in the manufacture of fully annealed, high-strength tying wire for balers. We have the knowledge to answer virtually any question you may have about the process.

The Process of Baling

What is a Baler?

Baler machines compress trash and waste materials for more efficient disposal. Inside each baler is a press that can generate enough force to compact cardboard boxes and other industrial or commercial trash into bales. These baled units get tied to help them maintain their form and shipped away for off-site disposal.

While baler machines typically handle soft plastic wrapping materials and cardboard boxes, they can also handle hard plastics, cans, and carpeting. Balers provide a far more efficient option compared to on-site trash bins because of their ability to save space and reduce the number of loads required to haul trash away.

Baling Process

The baling process involves depositing loads of soft or moderately hard trash into a baler machine. The interior press then forces the trash into a compact, standard-sized block, which is then tied or strapped into shape.

Balers have strong steel frames and a sturdy design that optimizes the structure, granting the equipment a long, functional lifespan with minimal maintenance. Design features may include precisely fitted main rams that minimize the risk of physical wear, anti-wear steel plates to reinforce the structure, and blade or shearing tools that equally distribute stress across the unit. High-performance balers use precision parts to eliminate misalignment and premature wear. This precision construction improves baling performance and reduces costs related to replacement parts and unscheduled downtime.

Some of the benefits of baling over uncompacted trash disposal include:

- Converting trash products into revenue-generating bales

- Minimizing loose waste and litter across a commercial, industrial, or construction sites

- Reduced transportation and disposal costs because compact trash requires fewer loads to remove and dispose of

Coastal Wire Products That Help With Baling

At Coastal Wire, we provide sturdy wire products for tying bales during storage and transportation. Our wire products are designed to provide strength and support in a wide range of environmental conditions. Our four most popular baling wire options include:

- Galvanized baling wire. This wiring has a zinc coating to prevent rust and corrosion from damaging the integrity of the wire. It’s rated as extra-strong, making it ideal for scrap metal, tire, and wood bales.

- Black annealed baling wire. Annealing is a finishing process that imbues metal materials with additional positive characteristics, such as resistance to corrosion. The annealing process imparts a protective black surface layer to the metal. Along with baling, this wiring sees frequent use in consumer processes, such as handcrafting.

- Single-loop baling wire. Our single-loop baling wire is sturdy and reliable enough for use with vertical balers, minimizing the risk of failure during feeding and tying. In vertical balers, wiring gets fed through the slots and wraps around the bales for operators to tie by hand. If the metal isn’t suitably strong, it will snap. Strong wiring saves operators from re-baling spilled trash.

- Double-loop baling wire. This wire is manipulated into perfectly formed loops that link together. It’s essential to choose double-loop baling wire from a reliable, high-quality provider. The loops must be identically sized to create a sturdy, reliable connection. Using lower-quality double-loop baling wire risks varying tensile strength among the loops around a given bale, which may cause the bale to distort or come apart completely.

About Coastal Wire Company

At Coastal Wire Company, we’re committed to creating high-quality baling wire products that provide structural integrity and reliable tying power for your bales. We understand that reliable wiring is integral to better recycling processes and greater adoption of balers. That’s why our products are high-strength, fully annealed, and easy to use. Contact us today to learn more about our different wiring products.