Annealed Wires

Wire is used throughout industry for a wide range of applications, from binding and securing small products together to providing the framework and support for large-scale structures. Manufacturers accommodate all of these applications by creating wire with different shapes, sizes, flexibilities, and formulations to suit various requirements and restrictions. One of the most commonly available types of wire is annealed wire.

Annealed wire—also referred to as annealed tie wire—is low-carbon steel wire that has been annealed to increase its ductility and decrease its hardness. These qualities result in higher flexibility without the loss of durability, which, combined, allow the wire to demonstrate self-tying and self-locking capabilities. It is available in several variations, each of which offers unique characteristics that make it suitable for different use cases.

In the following article, we provide a comprehensive overview of annealed wire, including what it is, how it’s made, the types available, and typical industrial applications.

What Is Annealed Wire?

As indicated above, annealed wire is low-carbon steel wire that has undergone the annealing process. The resulting product is soft and durable, qualities that allow it to remain intact when used in one of its most common applications—i.e., tying around itself or another product. For this reason, it is also sometimes called annealed tie wire.

How Is Annealed Wire Made?

Annealing is a heat treatment process that involves heating a material above its recrystallization temperature and cooling it back to room temperature. The cooling stage for ferrous materials (e.g., steel) is more gradual than that of non-ferrous materials (e.g., brass and copper) to prevent the metal from cracking or becoming brittle.

Many metalworking processes increase the hardness of material, which can make it harder to complete subsequent manufacturing operations. Annealing increases the ductility and decreases the hardness of the material, resulting in better formability and machinability. These qualities are essential for many wire applications.

The manufacturing process for annealed wire is as follows:

- Forming the wire from steel (typically low-carbon steel)

- Heating the wire to above the base material’s crystallization point but below its melting point

- Gradually cooling the heated material to below its crystallization point

- Applying oil to prevent rusting and facilitate dispensing through machinery (for black annealed wire)

The Annealing Process at Coastal Wire

At Coastal Wire, we use bell annealing furnaces to achieve a full annealing process that yields a consistent finish with no weak spots. Rather than relying on open-air heating or rapid cooling—both of which can introduce variation into the final wire product—we work with top-of-the-line equipment and thoroughly regulated production methods. Other annealing processes like strand annealing—sometimes used to save money—can’t compete with the thoroughness and quality of full annealing.

Types of Annealed Wires

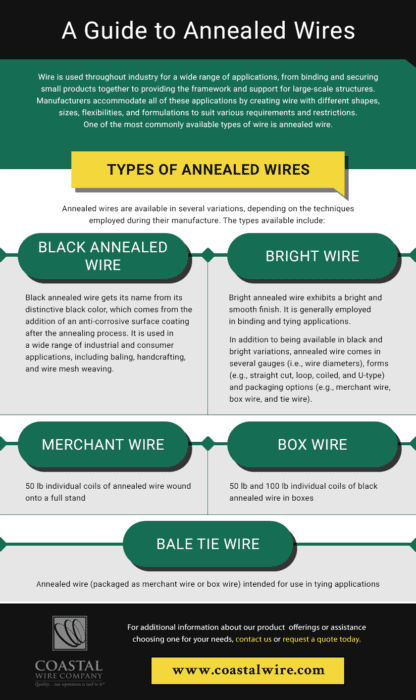

Annealed wires are available in several variations, depending on the techniques employed during their manufacture. The types available include:

- Black annealed wire. Black annealed wire gets its name from its distinctive black color, which comes from the addition of an anti-corrosive surface coating after the annealing process. It is used in a wide range of industrial and consumer applications, including baling, and handcrafting.

- Bright wire. Bright annealed wire exhibits a bright and smooth finish. It is generally employed in binding and tying applications.

In addition to being available in black and bright variations, annealed wire comes in several gauges (i.e., wire diameters), forms (e.g., straight cut, loop, coiled, and U-type) and packaging options (e.g., merchant wire, box wire, and tie wire).

- Merchant wire: several large coils of annealed wire wound onto a stand

- Box wire: smaller and tighter coils of annealed wire weight individually packed into boxes

- Tie wire: annealed wire (packaged as merchant wire or box wire) intended for use in tying applications

Applications of Annealed Wire

Due to its flexibility and durability, annealed wire is employed for binding and tying purposes in a wide range of industries, including the following:

- In the agricultural industry, it is used to bale branches and hay.

- In the construction industry, it is used to set iron and creating fencing and fence elements.

- In the manufacturing industry, it is used for general baling, binding, and tying applications.

- In the mining industry, it used to bind raw materials together and secure equipment.

- In the packaging industry, it is used to secure product packaging as well as produce wire mesh for packaging molds.

- In the recycling industry, it is used to tie scrap material—such as cardboard, metal, or paper—for easier transport through the processing facility.

In addition to its uses in the industrial sector, annealed wire is also utilized in the commercial and consumer sectors to produce products such as artwork and artisan crafts.

Why Choose Coastal Wire?

Annealed wire plays a key role in many industrial and commercial applications. Its flexibility and durability make it ideal for securely and safely tying materials and goods together. For superior wire products, turn to the experts at Coastal Wire.

Founded in 1978, Coastal Wire has since developed a reputation for high-quality wire. We offer a broad selection of products with various gauges, coil break ranges, and tensile strengths, including:

- Bale ties

- Box wire

- Bright wire

- Straight and cut wire

- Catch weight and soft coils

- Double-loop bale ties

- High-tensile galvanized wire

Our team has spent decades perfecting our manufacturing operations to produce the best wire products available on the market. By partnering with us for their wire needs, our customers benefit from our:

- Industry experience. We’ve produced industrial wire for over four decades. While we originally created wire for the bedding industry, we are now committed to supplying fully annealed baling, tying, and specialty wire to the recycling and galvanizing industries.

- Manufacturing facility. Our 100,000-square foot manufacturing facility is fully equipped with the forming and annealing equipment required for producing coiled wire, box wire, bale ties, and straightened and cut wire.

- Product quality guarantee. We offer free replacement of wire products that are found to have defects or manufacturing issues.

- Technical assistance services. For customers experiencing issues with their wire products in tying applications, we offer free technical help. Additionally, we test the wire employed to ensure it meets the requirements and restrictions of the specific application.

For additional information about our product offerings or assistance choosing one for your needs, contact us or request a quote today.