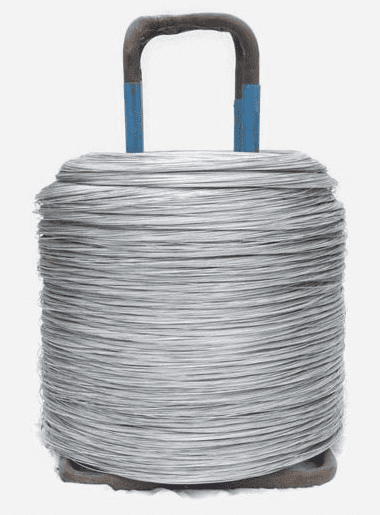

Galvanized Steel Wire

Coastal Wire Company specializes in the production of fully annealed, high-strength wire products for the agricultural, construction, manufacturing, mining, packaging, and recycling industries. Our product selection includes galvanized steel wire, a versatile and durable wire that can withstand corrosive conditions and harsh outdoor environments. Strengthened by the galvanization process, this type of wire is ideal for everything from rust-resistant fences to durable baling fasteners.

Coastal Wire Company specializes in the production of fully annealed, high-strength wire products for the agricultural, construction, manufacturing, mining, packaging, and recycling industries. Our product selection includes galvanized steel wire, a versatile and durable wire that can withstand corrosive conditions and harsh outdoor environments. Strengthened by the galvanization process, this type of wire is ideal for everything from rust-resistant fences to durable baling fasteners.

What is Galvanized Wire?

Galvanized steel wire refers to steel wire that has been submerged in a molten zinc bath to create a thin layer of zinc on the wire’s exterior surface. This zinc coating gives the wire a bright, shiny appearance while protecting it against corrosion and oxidation in high-moisture environments. In addition to corrosion protection, the zinc layer also acts as a physical barrier that protects the underlying wire from scratches, chips, and premature wear. These attributes make galvanized steel wire an effective and affordable wire solution for fencing, baling, and other outdoor applications requiring enhanced protection.

Applications of Galvanized Steel Wire

Galvanized steel wire is versatile, easy to produce, and low in cost, making it a preferred wire option for several domestic and industrial applications. These include:

- Fencing and Enclosures: Galvanized steel wire is commonly used to create chain-link fencing, welded wire mesh, and other protective perimeters that help secure various types of property. For example, agricultural sites often use galvanized steel wire to create fencing for chicken coops, enclosed ranch areas, and barnyards. The zinc coating allows the steel wire to withstand livestock damage as well as constant exposure to abrasion, moisture, and other outdoor elements. Cutting through the wire is also extremely labor-intensive, making trespassing difficult.

- Hanging Support: With its high tensile strength, galvanized steel wire is a great option for securing expensive pictures, artwork, mirrors, and home decor to walls. In agriculture or gardening applications, high tensile galvanized steel wire can be used to hang equipment such as watering lines and planters.

- Securing Windows: The strength, flexibility, and corrosion resistance of galvanized steel wire makes it a preferred option for securing or locking down windows on the outside of buildings or homes. This helps keep the interior space well-insulated and safe from intruders.

- Binding, Tying, and Baling: Galvanized steel wire can withstand corrosive conditions and mechanical stress, making it ideal for binding materials together or supporting large structures in outdoor environments. Examples include:

- Tying tall or top-heavy crops to support structures in gardens, vineyards, and greenhouses

- Binding raw materials and securing equipment in mining applications

- Baling branches, hay, and other materials in agricultural settings

- Binding materials at construction sites to prevent falling hazards or facilitate easier transportation

- Recycling: The recycling industry uses galvanized steel wire to bind and compress waste paper, plastics, and other scrap materials. In addition to saving space, this allows for easier and more efficient transportation of items through various areas of the facility.

- Packaging: Galvanized steel wire provides a strong yet durable binding solution for wrapping and securing items before transportation or shipment.

Benefits of Galvanized Steel Wire

Galvanized steel wire provides several key benefits over alternative wire options, especially in corrosive or outdoor environments. These include:

- Corrosion Resistance: As an iron-containing metal alloy, steel is prone to corrosion and degradation when exposed to humid or wet conditions. The galvanization process provides steel wire with a protective layer of zinc that shields it from the damaging effects of constant oxygen and moisture exposure. This allows it to last significantly longer than untreated steel wire, especially in caustic environments.

- Complete Protection: Fences, wire ties, and other wire products tend to encounter high levels of abrasion and harsh weather conditions. The layer of zinc in galvanized steel wire not only prevents corrosion but also protects against scratches, breakages, and other forms of mechanical stress. This allows them to provide complete protection from chemical and physical challenges in a range of applications.

- Low Cost: Compared with other treated or coated steel wire products, galvanized steel is generally a much more affordable and lower maintenance option. The galvanization process eliminates the need for additional surface preparations, coatings, or paintings, allowing it to be used immediately upon delivery. Galvanized steel wire is also stronger and longer lasting than alternative wire options, which limits breakages and minimizes repair and replacement costs.

- Ease of Inspection: Unlike other types of coatings or paints, the quality and consistency of the zinc coating in galvanized steel wire can be easily evaluated through simple visual inspections or non-destructive thickness tests.

- Long Life: Galvanized steel wire is incredibly long-lasting, providing roughly 20-25 years of life in harsh or high-moisture conditions. In dryer or less severe environments, galvanized steel wire products can last 50 years or more.

Galvanized Steel Wire Solutions at Coastal Wire Company

Galvanized steel wire provides long-lasting, reliable performance in a range of outdoor fencing, binding, and baling applications. An outer coating of zinc allows the steel wire to resist chips, scratches, cuts, and corrosion while maintaining its flexibility and ease of use.

At Coastal Wire Company, we manufacture innovative and easy-to-use baling, tying, and specialty wire solutions for a range of industries. The superior performance of our wire products comes from a combination of high-quality starting materials and a unique annealing technique that has been specifically adapted for the production of baling and tying wire. This results in a product that is durable enough to withstand its surrounding environment yet flexible enough to wrap around itself or other products several times.

We maintain a 100,000-square foot production facility equipped with annealing furnaces, forming equipment, and other machinery required to produce everything from straightened and cut wire to coiled wire, box wire, and bale ties. By partnering with us, customers benefit from:

- Over 40 years of industry experience

- Free replacements for defective or malfunctioning products

- Technical support for customers experiencing issues with tying

- Thorough product testing to ensure all functional and environmental requirements are satisfied

Contact Coastal Wire Company

To learn more about our galvanized steel wire products and other wire solutions, please contact us today or request a quote.