The Process of Steel Annealing

Annealing is a heat treatment used to enhance the ductility and hardness of metals to make them easier to fabricate into finished products. Manufacturers heat the metal to a point above its recrystallization temperature for a set period of time and then cool it at a specific rate to establish the desired molecular structure and chemical properties. Different metals are treated in ways specific to their molecular makeup and intended use. For example, iron, steel, and other ferrous metals are allowed to cool slowly at room temperature, whereas other metals may be quickly air-cooled or quenched in water.

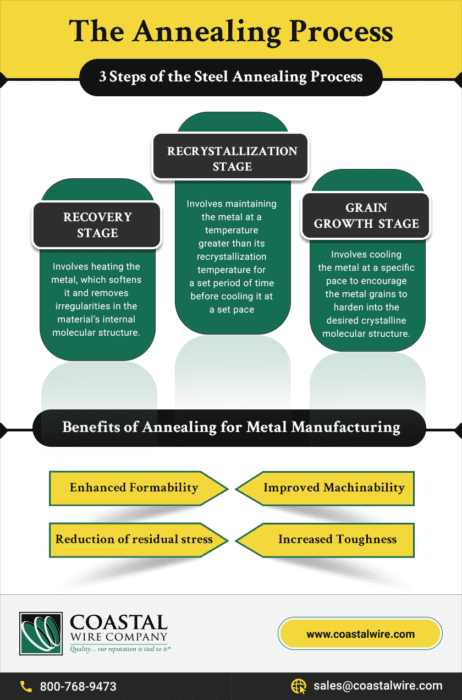

The annealing process offers a variety of benefits for metal manufacturing, including:

- Enhanced formability

- Improved machinability

- Reduction of residual stress

- Increased toughness

Annealing also reduces the overall brittleness of ferrous metals and alters the crystalline structure to enhance magnetic and electrical properties.

What are the 3 Steps of the Steel Annealing Process?

While the process can be modified slightly for different formulations and applications, annealing carbon steel and other steel blends always follows the following three steps:

- Recovery Stage. Recovery involves heating the metal, which softens it and removes irregularities in the material’s internal molecular structure. By removing internal stresses, the metal recovers its original characteristics, including electrical conductivity and thermal expansion.

- Recrystallization Stage. The recrystallization stage involves maintaining the metal at a temperature greater than its recrystallization temperature for a set period of time before cooling it at a set pace. This encourages the growth of new stress-free crystals.

- Grain Growth Stage. This third stage of annealing involves cooling the metal at a specific pace to encourage the metal grains to harden into the desired crystalline molecular structure. Depending on the intended results, this can involve cooling at room temperature; air cooling; or quenching in water, saltwater, or oil. Steel is typically quenched to enhance hardness.

Coastal’s Batch Steel Annealing Process

At Coastal Wire, we pride ourselves on using the latest annealing technology to produce superior quality annealed steel. Our bell-type annealing furnaces provide consistent annealing throughout the workpiece, without any weak spots. Unlike open-air heating and rapid cooling methods, our highly regulated annealing process does not introduce any inconsistencies or variations in the final product.

Coastal Wire uses batch annealing to heat our wires. The process helps to ensure that our wires exhibit the highest degree of strength and durability while offering the expansion and elongation necessary for heavy-duty baling applications. More traditional strand annealing only heats steel wire for a few minutes before rapidly cooling it, making for a less durable, less consistent material. Our wire, on the other hand, is heated in batches for several hours and then allowed to cool slowly. This creates a typical elongation of 25%, which significantly reduces the potential for wire breakage during automatic baling operations.

High-Quality Wires for Long-Term Performance

At Coastal Wire, we are committed to ensuring that our customers receive only the highest quality wire on the market. We adhere to a no-shortcut philosophy when it comes to our annealing process. Our longer annealing process ensures that your baling wire is durable and break-resistant, so you can rest assured that your materials will get from point A to point B without issue. In fact, we are so confident in our annealed wires that if they break, we will replace them for free.

With more than 40 years of experience manufacturing fully annealed baling wire, we know that every application has different needs. Our baling wire is available in 50 lb and 100 lb box coils for automatic balers, as well as single-loop bale ties for hand baling. All of our products are subject to extensive metallurgical testing throughout the manufacturing process, from direct approval of rod purchases through shipping. We also offer expert troubleshooting, testing, and consulting services to help you solve tying problems and determine whether the wire you’re using is up to standard.

At Coastal Wire, our reputation speaks for itself, with the lowest rate of wire breakage in the industry and verified quality over other baling wire manufacturers. To learn more about our batch annealing process and baling wire solutions, contact us today or submit a request for information.