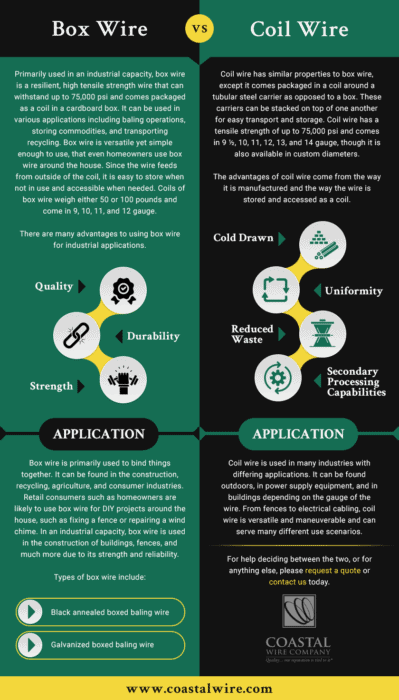

Box Wire vs Coil Wires

Box Wire

Primarily used in an industrial capacity, box wire is a resilient, high tensile strength wire that can withstand up to 75,000 psi and comes packaged as a coil in a cardboard box. It can be used in various applications including baling operations, storing commodities, and transporting recycling. Box wire is versatile yet simple enough to use, that even homeowners use box wire around the house. Since the wire feeds from outside of the coil, it is easy to store when not in use and accessible when needed. Coils of box wire weigh either 50 or 100 pounds and come in 9, 10, 11, and 12 gauge.

There are many advantages to using box wire for industrial applications.

Quality

Free of imperfections such as rust and mill scale, box wire has an aesthetically pleasing, uniform appearance that indicates its reliability and quality. While other types of wire come wrapped in exposed spools or coils, box wire comes packaged in a box that guarantees that the wire within it is protected from the elements before it reaches the hands of the end consumer.

Durability

Box wire is durable and resilient while remaining malleable. It easily takes on the shape of whatever it wraps around without breaking or stretching, as long as it is applied with its tensile strength in mind. During transport, the boxes protect the coils from rubbing against each other and causing unnecessary wear, ensuring an undamaged product that is ready to use at a moment’s notice.

Strength

With a tensile strength of up to 75,000 psi, box wire is perfect for the rugged application of wire in an industrial capacity. Maxing out at a diameter of only .135 inches, box wire is still strong enough to bind heavy bales of hay together or store shipping commodities before transport.

Application

Box wire is primarily used to bind things together. It can be found in the construction, recycling, agriculture, and consumer industries. Retail consumers such as homeowners are likely to use box wire for DIY projects around the house, such as fixing a fence or repairing a wind chime. In an industrial capacity, box wire is used in the construction of buildings, fences, and much more due to its strength and reliability.

Types of box wire include:

- black annealed boxed baling wire

- galvanized boxed baling wire

Coil Wire

Coil wire has similar properties to box wire, except it comes packaged in a coil around a tubular steel carrier as opposed to a box. These carriers can be stacked on top of one another for easy transport and storage. Coil wire has a tensile strength of up to 75,000 psi and comes in 9 ½, 10, 11, 12, 13, and 14 gauge, though it is also available in custom diameters.

The advantages of coil wire come from the way it is manufactured and the way the wire is stored and accessed as a coil.

Cold Drawn

When coil wire is manufactured, it undergoes a process called drawing, which pulls or draws the wire into shape. This process occurs at room temperature and grants an aesthetically appealing finish, better machinability, higher tensile strength, and better uniformity throughout the wire.

Uniformity

Rigorous quality control measures during manufacture guarantee that coil wire is free of burrs and other blemishes that can cause the wire to look unappealing and adversely affect its performance. These measures also allow different spools of coil wire to have close tolerance lengths.

Reduced Waste

When utilizing coil wire in the field or on a job site, its design allows for less waste due to the continuous nature of the spool. If used in a machine, the spool can be directly fed into the machine, causing fewer drops and remnants from having to cut and reposition the wire.

Secondary Processing Capabilities

Coil wire is great for finished or half-finished parts. It can easily be bent, flattened, swaged, drilled, welded, or punched through a part, and its ends can easily be threaded or chamfered.

Application

Coil wire is used in many industries with differing applications. It can be found outdoors, in power supply equipment, and in buildings depending on the gauge of the wire. From fences to electrical cabling, coil wire is versatile and maneuverable and can serve many different use scenarios.

Can’t Decide Which Wire Is Best? Get Help from the Experts at Coastal Wire

Box wire and coil wire are similar in most ways, including appearance and strength. The two differ mostly in how they are stored and how the wire is drawn from the spools, which allows the two wires to serve different uses and industries.

At Coastal Wire, we produce both box wire and coil wire, and consider ourselves to be South Carolina’s leading wire expert, as well as the largest box wire manufacturer in the nation. For help deciding between the two, or for anything else, please request a quote or contact us today.